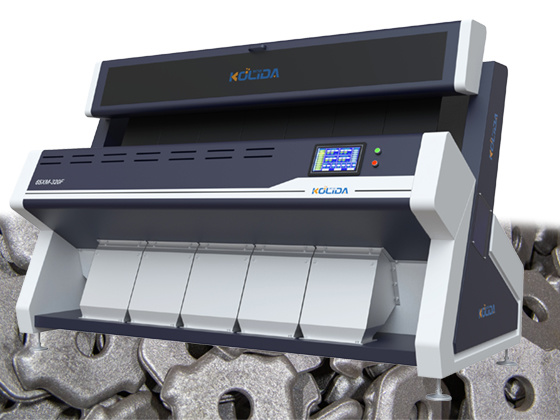

Plastic recycling sorting line polyester flake color sorter

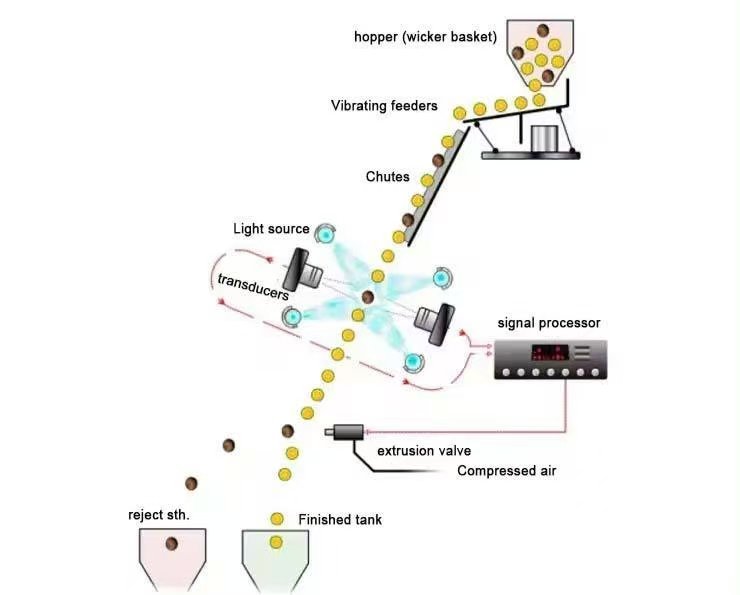

Working Principle

- The material enters the machine from the aggregate hopper at the top, and through the vibration of the feeding device, the selected material is dropped along the feeding distribution chute.

- The material passes through the chute. The vibrator at the top end accelerates the material down the chute into the sorting box.

- After entering the sorting box, from the image processing sensor CCD and the background device through the role of the light source, the CCD accepts the synthesized light signals from the selected materials, so that the system produces output signals, and amplified and processed and transmitted to the FPGA + ARM algorithmic processing system, and then by the control system to send out commands to drive the action of the jet solenoid valve, which will be the different colors of particles blown to the discharge of the hopper of the waste chamber flow away.

- The good selected materials continue to fall to the receiving hopper of the finished product chamber out, so that the selected materials to achieve the purpose of selection.

| Model | Power of the whole machine (kw) |

Supply Voltage (v) |

Gas Pressure (Mpa) |

Size (mm) |

| M32 | 0.5 | 220 | 0.6-0.8MPa | 420*1100*1320 |

| M64 | 0.5 | 220 | 0.6-0.8MPa | 585*1504*1660 |

| 65XM-64F | 0.8 | 220V/50Hz | 0.6-0.8 | 880*1504*1760 |

| 65XM-128F | 1.3 | 220V/50Hz | 0.6-0.8 | 1314*1504*1760 |

| 65XM-192F | 1.9 | 220V/50Hz | 0.6-0.8 | 1650*1504*1760 |

| 65XM-256F | 2.4 | 220V/50Hz | 0.6-0.8 | 1986*1504*1760 |

| 65XM-320F | 3 | 220V/50Hz | 0.6-0.8 | 2322*1504*1760 |

| 65XM-384F | 3.6 | 220V/50Hz | 0.6-0.8 | 2658*1504*1760 |

| 65XM-448F | 4.1 | 220V/50Hz | 0.6-0.8 | 2994*1504*1760 |

| 65XM-512F | 4.7 | 220V/50Hz | 0.6-0.8 | 3330*1504*1760 |

| 65XM-640F | 5.8 | 220V/50Hz | 0.6-0.8 | 3666*1504*1760 |

| 65XM-768F | 5.5 | 220V/50Hz | 0.6-0.8 | 4996*1697*2260 |

Note: The above processing capacity is calculated according to the material with 15% impurity content.

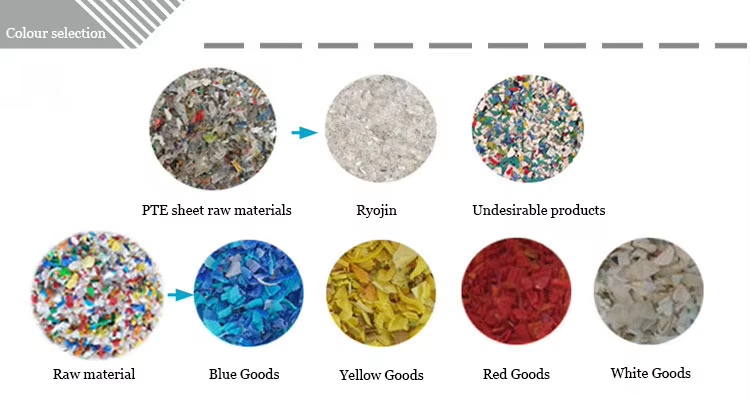

Sorting Cases

Optional ABS/PP/PC/PE/PET plastic bottle caps, plastic pellets, etc.

Core Technology

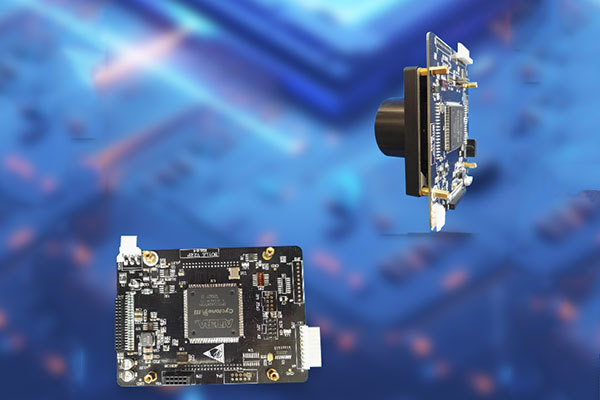

High-performance processing chip

The main control system adopts ARM9 series high-end embedded processor chip, which effectively improves the control speed and color selection precision.

CCD High Definition Industrial Lens

Using 2048 high-performance CCD image sensor, color selection resolution of up to 0.07mm, can clearly perceive the small color differences in the local disorientation.

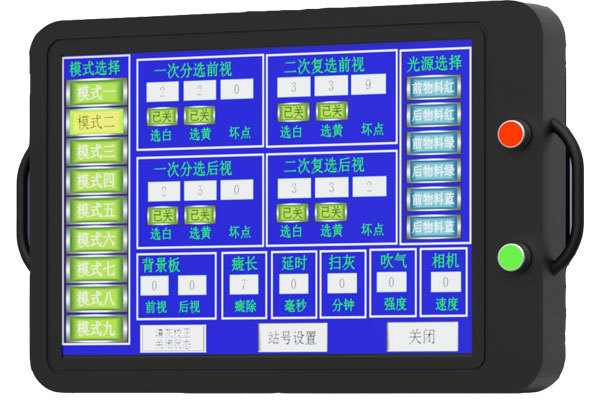

Simpler and more convenient operation

The operation interface adopts industrial-grade 10-inch TFT color touch screen, the parameter setting is simple and easy to operate, and a variety of presets can be set up for one-key sorting.

Big data analytics

To create an open massive database, storage unlimited, integrated with a wide range of material solutions, to achieve one machine, multi-selection, multi-purpose, a single machine can be completed at the same time the second selection, three selection, four selection, reduce the take-out ratio.

After-sales guarantee

One Year Warranty Lifetime Maintenance

Customer service online

7*27 hours of service

home teaching

Professional engineer hand-in-hand teaching

Remote operation

Engineer remote upgrade maintenance

Free installation

Special personnel logistics transportation

Regular home visits

Regular on-site technical maintenance

Formal invoice

One Year Warranty Lifetime Maintenance

7 days return

Can not reach the contract effect can be returned

Technical strength

Honor

Kelida Intelligent Equipment (Shandong) Co., Ltd.

national high-tech enterprise

Focus on service color selection process

Products are exported to more than 100 countries and regions

The factory covers an area of 20000 ㎡

ISO9001

National consumers rest assured brand