Product classification

online message

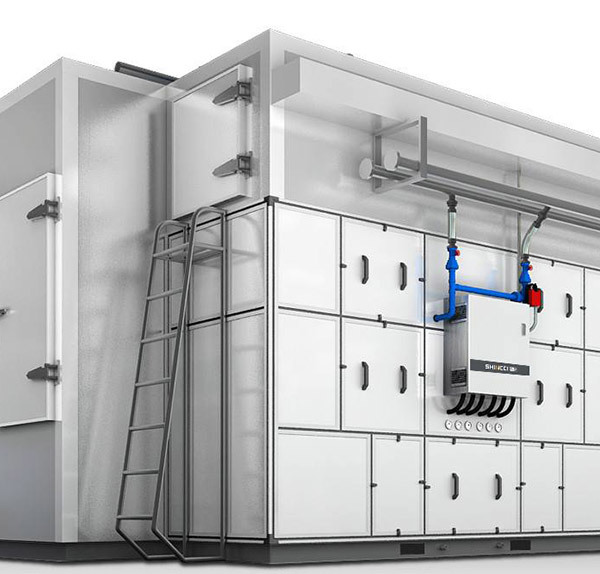

Industrial dryers

- Commodity name: Industrial dryers

- Description

-

Product Overview

An industrial dryer is a device used to dehydrate and remove moisture from wet or damp materials. It evaporates and discharges the moisture in the material by providing heat, airflow and proper processing conditions, thus realizing the drying of the material. The dryer is widely used in various industrial fields, such as food processing, chemical industry, pharmaceutical industry, metallurgy, building materials and so on.

By heating the air or airflow, the heat will be transferred to the material, so that the moisture in the material will be evaporated. At the same time, the fan inside the dryer discharges the water vapor and maintains the dry environment. Utilizing a radiant heating source, such as infrared or microwave, to directly transfer heat to the material to evaporate the moisture.

Dryers typically have a compact structural design with a relatively small footprint, saving factory space. However, there are some limitations and considerations with dryers. For example, different materials have different requirements for drying conditions, which need to be adjusted according to the actual situation. In addition, too high temperature and too long drying time may adversely affect the quality of materials.

Product features

1. Minimum moisture content of sludge can be controlled at 2%.

2. Dust automatic recovery: to ensure the cleanliness of the equipment.

3. Medium and high temperature sterilization: to reduce the active odor of the sludge.

4. Internet of things online adjustment: support cell phone operation and warning

5. Non-standard customization: 1 ton to 20 tons per hour for a single unit of equipment.

6. Zero Emission: No odor emission during operation.

7. Heat source: support electricity, flue gas steam hot water, gas, etc.

8. Automatic adjustment: 50% 2% adjustable water content after drying.

Product Parameter

Working Principle

KLD .WD series belt dryer is a kind of drying equipment which can be produced in batch and continuous. The dryer consists of several units, the chain is dragged by the conveyor to move back and forth in the dryer, and its running speed can be freely adjusted according to the temperature of the material. The hot air flows through the material, and part of the heat generated is absorbed by the material, and part of it forms the water vapor to be discharged from the moisture discharge holes, and the discharged exhaust is discharged by the special moisture discharge fan, so as to achieve the purpose of drying. The dried finished products fall into the collector continuously. The length of the box is combined by the standard section, in order to save space, the drying machine can be made into a multi-layer type.

Photographs show

Process Flow

①Wet silo ⇒ ②Conveyor ⇒ ③Uniform fabricator ⇒ ④Belt dryer ⇒ ⑤Bagging/Stacking ⇒ ⑥Transportation/Storage

Part of the process

Closed type/Continuous operation/EIA compliance

Underground silo

Closed Conveyor

Dryer Mainframe

Part of the case show

Our Advantages

► Reduced operating costs

► Reduce equipment investment

► Support case study

► Free design program

► Multiple heat source options

Four reasons to choose us

Strength factory

With large physical plant, 30 sets of production equipment

Abundant cases

Rich cases in various industries, support customers to visit the site

Quality Assurance

Selected raw materials are strictly screened to ensure product quality.

Technical support

With professional after-sales customer service, provide technical guidance

Company Profile

Quality Assurance/Widely Used/Technical Support

Shandong Kelida is a collection of research and development, design, sales, production in one of the manufacturers. The company's main equipment for drying equipment (sludge drying equipment, flash dryer, belt dryer, drum dryer, disk dryer, spray dryer, air dryer, rotary dryer,). According to the material form, viscosity, moisture content, choose the right equipment for you.

Focus on cutting-edge academic. Gathering - batch of elite talents and business backbone who have been engaged in this industry for a long time, with many engineers and technicians. We have rich experience in R&D and manufacturing. And with many international counterparts to maintain frequent technical exchanges and cooperation, with a strong technical strength and perfect quality assurance system. Facing the competitive market, our company adheres to the business philosophy of “Doing things seriously, the wider the road goes”, and constantly strengthens the development of new products. Pursuing the idea and then line, seek quality, line and then constant dedication to the quality of effort to achieve customer satisfaction,” the quality policy of the Kelida staff warmly welcome the respected users, friends from all walks of life to visit the guide to discuss business!

Key words:

Previous:

Next: