News

Do you really know anything about color sorters?

2024-09-11

StarBurst

China Powder Network

Color sorter - as the name suggests - is a machine that screens materials according to their color. With the development of technology, the color sorter is not only limited to the screening of material color, but also material shape and other aspects of screening.

Color Sorter Working Principle And Structure

Color sorter is based on the material color or shape differences, through photoelectric detection and image processing means to achieve material sorting and purification of optoelectronic equipment, which is used in a large number of food and ore screening field, and because of its high selection rate, impurity rejection rate and bring out the ratio of the rapid promotion.

Usually, the color sorter is divided into 4 parts according to its function machine structure and other components, such as feeding system, irradiation and detection system, information processing system, separation execution system, etc., and the role of each part of the system is as follows:

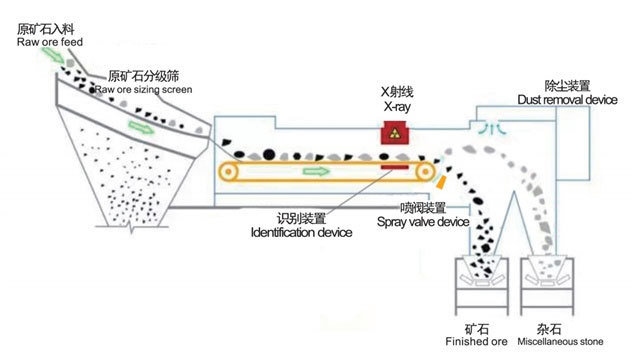

(1) Feeding system: the feeding method is mainly belt and inclined chute, etc. The feeding system is used to convey the raw ore, and the raw ore will be irradiated through the system set up to achieve the purpose of separating the raw ore.

(2) irradiation detection system: as the main core part of the color sorter, it is mainly based on the color of the ore, gloss and other characteristics of the information collected as the ore sorting system. Among them, the irradiation part is mainly the use of light source and other materials, the detection part is mainly on the ore in the light source, rays and other external conditions, the use of X-ray fluoroscopy technology and infrared and other sensors to detect its feedback information.

(3) information processing system: information processing system for the whole color sorter control part, equivalent to the brain center, with analysis and decision-making control role. Mainly based on the detected signals, to complete the identification task, will drive the separation signal, after the amplifier and other equipment for further processing.

(4) Separation execution part: the separation execution part mainly accepts the signal of the information processing system, and separates the ore or waste rock from the original movement track.

Problems in practical application

In the actual application, our color sorter also has a variety of problems.

Material problems

Color sorter in actual use, in grain and agricultural by-products processing, often because of different shapes, raw materials with different impurity rates, material dust and other factors, color sorter work nozzle easy to clog, electronic control control system and valve nozzle coordination does not match, some with rice color sorter to tea, plastic parts, ores, etc., resulting in color sorter can not be adapted to the current situation, the color effect of color sorter can not achieve the desired effect, thus disputes arise.

Reliability problem

Color sorter manufacturers, due to insufficient technical reserves, the loss of key personnel, resulting in the color separation of different materials in the design, because of lack of experience, ill-considered, the design inevitably exists in the inherent shortcomings of the problem. In addition, there are some flaws in the production, inspection, installation, and some of the reliability of the work is not up to the promise of the enterprise.

Environmental problems

Color sorter is a high-tech products, for the working environment has high requirements. However, in actual use, the enterprise is difficult to do in accordance with the specified environmental requirements, thus affecting the use of color sorter.

Process matching problem

At present, most of the color sorters are applied in the processing of grain, agricultural and sideline products, due to the rapid development, the process route is not very clear, and the technical level of its operators is uneven, resulting in large errors in the color selection results can not meet the ideal requirements.

Wrap-Up

Color sorter set light, machine, electricity, gas and other high-tech in one, is widely used in material sorting, to improve the quality of materials and products. In recent years, the domestic color sorter in technology to accelerate the pace of innovation, production enterprises in the search for growth, in the innovation of breakthroughs, the key components of the replacement, the first line of products in the stability, reliability and high-precision sorting effect and other aspects of maturity.

Key words:

Next:

Related News